Stills and Distillation

* Source : Les routes de la lavande

Photo : "Tourniaire” 300-liter open-fire still used in the 30s. Ph. Gagnepain.

Stills

Widespread use of mechanical exploitation equipment has led to displacing high altitude cultivation toward lands in plateaus and valleys.

Distilleries today are less numerous but larger.

The tasks are often mechanized. Fuel oil, gas and electric power have often replaced distilled straw as combustion material but, in the current context of sustainable development, studies of reverting to using straw in higher performance boilers are underway.

A new technique imported from the United States employs caissons pulled by tractors whereby the plants are cut, ground and harvested directly into a “trailer container”.

Taken to the distillery, it receives a cover and is connected to steam and refrigerant supplies. The container serves as the distillation column’s bottom reservoir.

Labor savings are very important. This technique, particularly suited for operation with large lavandin fields, is little used for lavender and is prohibited for PDO certification, as the essential oils obtained have different characteristics from the traditional standards.

Technical development of the stills

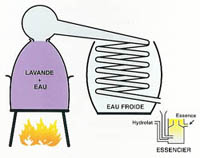

Simple mobile open-fire still

Capacity : 100 to 500 liters.

Capacity : 100 to 500 liters.

Duration of batch : about 3 hours.

Fuel type : pine or oak, genêts (broom bush).

As the flowers do not separate from water, they cannot be used later for fuel.

* Simple mobile open-fire still - Source : "Jardin des arômes", Nyons

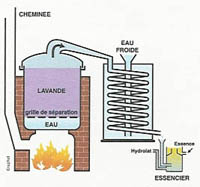

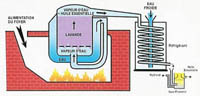

Fixed open fire still

Capacity : 200 to 800 liters.

Capacity : 200 to 800 liters.Duration of batch : 2 to 3 hours.

Fuel type : wood, distilled straw, coal.

The tank, whose volume has been increased, is protected by masonry insulation which reduces energy losses.

The use of a hoist and basket was adopted to separate the flowers from the water and then use them later as fuel.

* Fixed open fire still

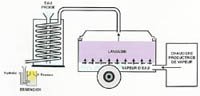

Steam still

Capacity : generally 1000 to 6000 liters per tank (up to 20 000 liters).

Capacity : generally 1000 to 6000 liters per tank (up to 20 000 liters).Duration of batch : 30 to 40 minutes.

Fuel type :distilled straw.

These steam stills and steam baths can also work with oil or gas boilers. Most distilleries were equipped until recent years with this type of still. Automation is now widespread.

* Steam still

Mobile distillation caisson

Capacity : 14 to 26 cubic meters per caisson.

Capacity : 14 to 26 cubic meters per caisson.

Duration of batch : 1 to 1.5 hours.

Fuel type : gas, electric power or fuel.

This system was developed in recent years, primarily for distillation of lavandin.

* Mobile distillation caisson

Source : "Jardin des arômes", Nyons