How is lavender essential oil made ? Extraction

The essential oil is completely natural and comprises countless varieties of aromatic molecules from the plant. Lavender essential oil is obtained by steam stripping of the plant; that is, by passing steam around and through the lavender tops in a still.

Extraction - Distillation

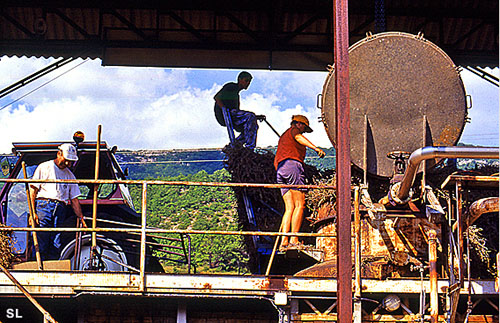

The harvest starts in July when flowering has ended and the color turns gray. The harvesting machines begin their work; gathering is done either in bulk or by bunches depending on the equipment used.

A short drying period precedes the distillation process.

The process

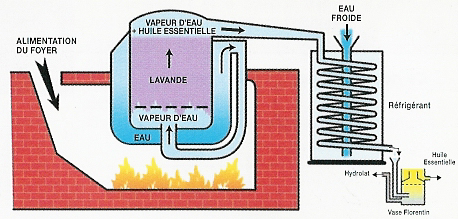

The flowering tops (stems and flowers) are put into a large volume vessel.

Once filled and well packed, the vessels are closed by air-tight covers and distillation starts.

Steam is passed through the vessel contents, vaporizing the essential oil.

Steam traverses the entire mass of lavender and, loaded with tiny droplets of essential oil, passes through a gooseneck into a serpentine pipe immersed in cold water.

The difference in temperature causes the steam-essential oil mixture to condense and drain into a drum (the “essencier”) where it is decanted.

The essential oil, having an average density of 0.888 to 0.894, is less dense than water and floats.

It is recovered using skimming equipment.

As the water phase contains only negligible amounts of fragrant material and is of little or no use, it is drained away.

The principles of extraction have changed little through the ages, but the equipment or stills employed have developed considerably.

In chemical engineering, this process is called “steam stripping”.

Another method of extraction: The Concrete and the Absolute

Extraction of the main odorants in lavender and lavandins can also be done by using solvents such as hexane or alcohol.

The cut flowers are steeped in a solvent that dissolves the aromatic components and is then evaporateed.

The remaining thick paste, called the "concrete,” is colorful, dark green and fragrant.

It contains waxes and fragrance and will be used mainly in soaps.

For perfumery end use, alcohol is employed: The "wax" that did not dissolve is separated by filtration. The remaining alcohol, loaded with soluble odorants, is evaporated leaving the essential oil called "absolute".

The concrete and absolute have nothing to do with the oil or gas obtained by steam stripping.

The “concrete” lavandin had its heyday in the 70s. It was cut early in the morning, loaded into trucks and taken the same day to factories in Grasse where it was treated immediately.

Today, its use has declined sharply and only lavender continues to be used; the perfume obtained - that is to say, "Absolute Lavender" is of higher quality than that from distillation and highly sought by perfume makers.